lundi 16 novembre 2020

What is a Thermowell?

What is a Thermowell?

A thermowell is a cylindrical fitting made to protect a sensor from high velocity flow, high pressures, corrosion and harsh environments that would otherwise damage the sensing element.

Thermowells protect the integrity of the sensor by acting as a medium between the process and the thermocouple or RTD probe. Thermowells are typically used with process piping and vessels. In those applications, they provide the added benefit of facilitating the replacement of the sensor while maintaining a closed system.

Does a Thermowell Affect the Temperature Sensor's Performance?

Although thermowells provide many advantages when it comes to protecting sensors from damage, they also affect the sensor's accuracy and responsiveness. The process fluid has to transfer heat to the thermowell, which then transfers heat to the sensor. With a sensor-thermowell assembly, more mass needs to be heated before the temperature is conducted to the sensor, thus slowing down the sensor's response and reducing its accuracy.

Thermowells remain nonetheless critical to process control systems for many applications. The following options offer different benefits depending on what the thermowell assembly will be used for.

Constuction Type

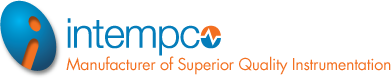

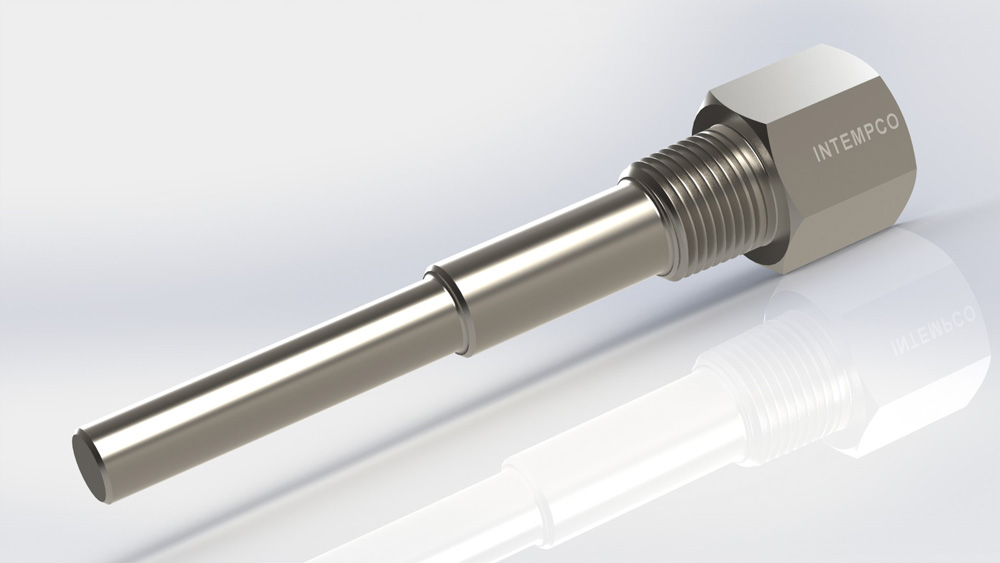

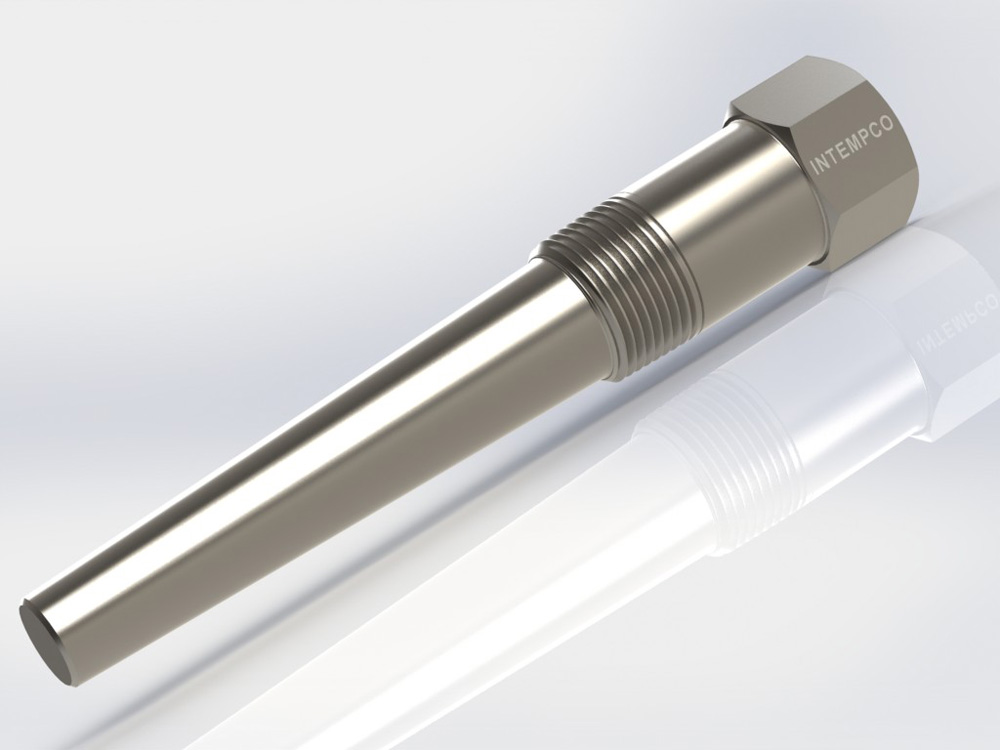

Barstock or Fabricated: Barstock models are machined from one solid piece of Hexagon or Round Bar. They offer the highest pressure ratings and strength. Fabricated models are multipiece welded and machined assemblies and come in a larger variety of sizes and lengths but have limitations for strength and durability under extreme conditions.

Intempco's industrial thermowells are available machined from solid bar stock or fabricated out of welded and machined contruction. Barstock thermowells are among the strongest model types due to their one piece construction. These models are available with threaded or socket-weld process connections and the immersion section (the stem) profile can be stepped, straight or tapered. Fabricated models offer less strength, but can have better temperature performance depending on models, have more options on sizes and configurations, and better cost on long lengths. Intempco also manufactures a wide variety of thermowells and protection tubes for all industries.

Process Connection

A thermowell's process connection can be threaded threaded, socket-weld, weld-In and flanged. Here's a brief description of each type:

#1 Threaded Process Connection

Threaded process for screwing into a female threaded process connection such as a threadolet, adaptor or directly to a tapped access port.

#2 Socket-Weld Process Connection

Socket-Weld for welding in place to a standard pipe size weldolet, pipe adaptor or directly to a pipe size process opening. The process connection diameter matches standard pipe dimensions.

#3 Weld-In Process Connection

Weld-In are similar to Socket-Weld, the only difference is the main diameter. This section is normally larger with standard dimensions such as 1.25" or 1.50" diameter.

#4 Flanged Process Connection

Flanged connections for mating to flanged process connections.

Stem Style Stepped and Reduced Tip

Characterizes the immersion section that will be in the process. Stepped thermowells, most popular, have a thick robust main stem section with the last 2.5 inches of the stem having a diameter of .50" to reduce thermal lag for better time response. Reduced Tip have an even smaller tip section then stepped models, and are available on certain light duty models for very fast time response.

Stem Style Tapered

Characterizes the immersion section that will be in the process. Tapered thermowells are the strongest mechanically. The stem starts off at a large root diameter and tapers down to the tip diameter. This design has a higher natural frequency making them more appropriate for systems with extreme dynamic conditions such as process lines with media flowing at high velocity.

Stem Style Straight

Characterizes the immersion section that will be in the process. Straight stem thermowells are similar to stepped stems, but the large diameter extends to the Tip. Time response is slower with this style. The heavy wall on the entire length of the stem gives them longer service life under conditions where erosion and/or corrosion exists. They are also well suited for the uniform application of protective coatings.

Bore Size

The bore is the section into which the probe is inserted. The bore size must be larger then the probe diameter to allow easy insertion. Clearance between probe and bore also prevents the probe from jamming due to overall assembly misalignment, diameter tolerances and straightness. Typical bore diameters are .010 inches (.25mm) larger then the probe diameters.

Material

Thermowells can be fabricated in a wide variety of materials depending on the application and process fluid they will be in contact with. Stainless Steel 316 is the most readily available.

Other standard materials are SS316H, SS304, SS304H, Brass C-360, Alloy 600, Hastalloy C-276, Aluminum 6061-T6 and Titanium Grade 2. Many other materials are available.

Insertion Length

A thermowell's insertion length - also called immersion length - is measured from the bottom of the thermowells process connection to the outside tip.

Lag Extension

Lagging extension is an extra length added to the thermowell outside the process. This is sometimes needed to move the instrument connection to clear pipe insulation or other obstacles, or to move the instrument connection away from extreme heat.

This extra length may also be required if thermowell is welded through a double wall tank and extra length is required on the weld diameter to enable welding inside and outside the walls.

Thermowell Stem Length

The thermowell's stem length should match your sensor assembly. It is measured from the top of the well to the bottom of the bore.

Instrument Connection

The instrument connection is where the probe, sensor assembly or instrument is connected to the thermowell. 1/2" NPT is the most common connection.

Visit Intempco's thermowell lines to make your purchase today.