Ensuring Hygiene and Safety: The Vital Role of 3-A Sanitary Standards

Discover how 3-A Sanitary Standards certified instruments ensure compliance with the strictest hygienic standards in food, dairy, and pharmaceutical processing. Learn what criteria makes these instruments suitable for such applications and how Intempco's products can help meet your hygienic standards.

Understanding the 3-A Symbol: Its Meaning and Significance in the Sanitary Processing Industry

The 3-A Symbol represents the 3-A Sanitary Standards, which are a set of guidelines developed by the 3-A Sanitary Standards, Inc. organization. This certification ensures that equipment and components used in food, dairy, and pharmaceutical processing applications are hygienic, easy to clean, and meet regulatory requirements.

Sanitary processing facilities must adhere to strict sanitation standards and regulations to prevent contamination and ensure that the products produced are safe for consumption.

The 3-A Sanitary Standards were introduced over a century ago in the dairy industry and have since become a standard in the food, beverage, dairy, and pharmaceutical industries. The program follows a high sanitation process and qualification check, providing two main advantages: easy manual cleaning and quick disassembly for inspection.

These standards were developed through collaboration with hygiene professionals, equipment manufacturers, and food producers. The certification provides assurance to all stakeholders, from farmers to regulatory agencies, that the equipment is designed and manufactured according to recognized and accepted standards.

By adhering to these standards, companies can ensure high sanitation processes and qualification control within their operations, minimizing the risk of contamination, reducing downtime and maintenance costs, and improving overall efficiency.

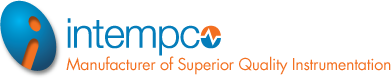

Intempco's 3-A Sanitary Sensors pictured above: the MS22, DT91 and RS80. Explore all Intempco's 3-A Sanitary Standards sensors here.

3-A Certification: What It Means and Why It Matters for Hygienic Processing Applications

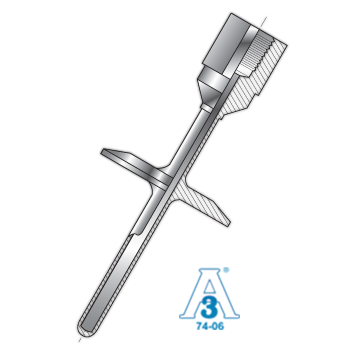

The 3-A Sanitary Standards, Inc. organization establishes design, construction, and performance criteria for an instrument to be certified, ensuring its suitability for hygienic applications. An instrument must meet specific requirements, including sanitary design, high-quality materials, controlled manufacturing, thorough testing, and ongoing compliance.

To ensure hygienic processing, the instrument must prevent bacteria accumulation, minimize contamination, facilitate cleaning, and use corrosion-resistant, chemically compatible, and wear-resistant materials. The manufacturing process must maintain consistency and quality, and the instrument must pass testing and inspection for compliance. Manufacturers must continuously maintain compliance with regular inspections and re-evaluations.

To be 3-A certified, an instrument must meet several specific requirements, including:

|

TW810: Sanitary Thermowell Welded to Tube, Fast Response |

|

3-A vs. Non-Certified Instruments: Understanding the Key Differences for Hygienic Processing Applications

Using 3-A certified instruments can provide several benefits and features for hygienic processing applications. These instruments are designed specifically for sanitary environments and are easy to clean, free from crevices where bacteria can grow, and constructed of materials compatible with food, dairy, and pharmaceutical processing. 3-A certification ensures that the instrument complies with regulatory requirements and industry guidelines.

The strict standards of 3-A certified instruments ensure consistent and reliable performance, increasing the overall quality of the instrument. Additionally, these instruments are designed to be compatible with other 3-A certified components, enabling easy integration into a hygienic processing system. 3-A certified instruments are also designed to minimize the potential for contamination, reduce the risk of foodborne illness, and ensure safe and consistent operation, promoting safety.

Efficiency is another benefit, as they are designed for easy cleaning, reducing downtime and maintenance costs, and improving overall efficiency. Finally, this certification provides a traceable record of the instrument's manufacturing and testing history, increasing confidence in the instrument's quality and safety. Therefore, using 3-A certified instruments is a wise choice for hygienic processing applications.

Upgrade your processing system with 3-A certified instruments today - This email address is being protected from spambots. You need JavaScript enabled to view it.

5 Benefits of Using 3-A Certified Instruments for Hygienic Processing Applications

Using 3-A Sanitary Standard certified instruments can offer several benefits, including:

- Compliance: helps to ensure compliance with hygiene standards, regulations, and guidelines for food, dairy, and pharmaceutical production.

- Safety: the certification ensures that the instruments meet rigorous sanitary design, materials, and construction requirements, reducing the risk of contamination and ensuring safe and consistent operation.

- Quality: instruments are manufactured to strict quality standards, ensuring reliable and accurate performance in harsh operating environments.

- Efficiency: designed for easy cleaning, reducing downtime and improving overall efficiency.

- Compatibility: ensures that the instruments are compatible with other certified components, enabling easy integration into a hygienic processing system.

Intempco: Your Trusted Source for 3-A Sensors

When it comes to hygienic processing, there's no room for compromise. That's why at Intempco, we're dedicated to providing the highest quality instruments to meet the most demanding standards in the industry.

With over 35 3-A certified sensors, a range of temperature monitoring and measuring instruments that can be custom to your application needs, we're the go-to source for sanitary temperature sensors. Our commitment to quality and compliance means you can trust our products to be easy to clean, resistant to corrosion, and free from crevices where bacteria can grow.

If you are unsure of your current supplier or product's certification status - look them up in the 3-A database of current certifications.

So why choose Intempco for your sanitary sensors? Because we understand the importance of hygiene and quality, and we're committed to delivering the best products and services to our customers. This email address is being protected from spambots. You need JavaScript enabled to view it. Our expert sales team is here to help you find the right instruments for your specific application, ensuring that you get the results you require with confidence.

|

|

|

|

|